Wilkinson Cycles Global HQ

Posted: April 30, 2015 Filed under: Uncategorized | Tags: bike frame storage, bike workshop, brass brazing, Brazing, butt gauge, butted tubing, cast iron surface table, dropout, fork bender, fork blade bender, fork end, frame building, frame jig, framebuilding, gas fluxer 4 CommentsHello again, I’m sorry I haven’t posted anything for a while but I’ve been busy doing stuff like this at my new workshop:

He should come in handy for those menial tasks..

Putting a horizontal mill together on top of a cast flypress stand. I’ll put a variable speed motor on it for tube mitring.

I cut all these tool slots on the Bridgeport mill out the back. We have a full machine shop on site.

I bought a number 4 flypress on a stand. I want to use this to form chainstay dimples, among other things.

I’ve now got the first increased-offset Sputnik Tool frame jig. I had to get the Park workstand base to attach it to my home-made stand.

I improved my gas economiser. Now my torch can’t rotate. I wish it was cordless as it appears to be here, but I just swapped it out for my bigger one to braze the fork crown.

My good friend John made this fork blade bender. The form goes from a 5″ radius to a 15″ radius. This was all made on a manual Bridgeport mill. The most I did was a bit of deburring and helping to lift the huge rotary table.

I had this “christmas tree” alignment gauge waterjet cut from stainless steel. It makes aligning a frame very easy. You zero the V onto the seat tube to check that the dropouts are centred and spaced correctly. I used London Waterjet’s finest cut.

I found this old suspension bump stop on the road. I drilled a hole in it so it now makes the post a bit safer in case I slip and put it through my arm.

Rick’s fork will be my first use of my new bender..

Preparing the fork blades for brazing. I used an end mill to slot the blades in the Bridgeport. A radius is less prone to forming cracks so I file the fork ends to fit.

This is the Paris Brest fork crown after brazing onto the steerer and a soak in the water tank. I gave it a little sanding and filing. It’ll get more love after the fork is made.

Stay tuned for my next post for bender performance, laser-sintered titanium dropouts and more!

My New Surface Table.

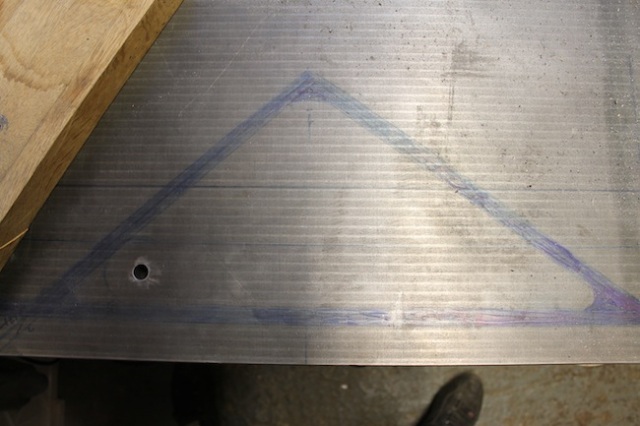

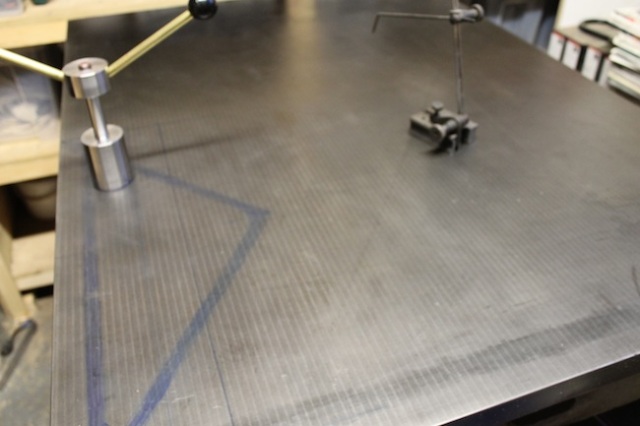

Posted: December 23, 2013 Filed under: Uncategorized | Tags: alignment table, bottom bracket post, cast iron surface table, frame building, surface plate, surface table, Wilkinson Cycles Leave a commentSo, as part of my quest to tool up in a proper manner, I decided to liberate a 4ft x 3ft cast iron surface plate from Glasgow University.

With the help of two Tirfor winches, a pallet truck and an engine hoist, my good wife and I brought the plate across the bridge to the island, down the steps and onto its base in the workshop.

50 years old but in fine fettle due in no small part to being kept with a protective wooden cover, I had one more task to do before it was ready for use.

I had to drill a hole through the plate to mount my bottom bracket post. Like some noisy hardened steel harpoon though the skin of a great silent whale, I broke through the 40mm hide of this grey leviathan and ran paper under thumb to smooth the burr. The fine hardened stainless steel post was made in the new world by Mr Alex Meade. The post is designed to be used with Park facing tool threaded inserts.

I measured and drew out the shape of the casting ribs on the underside of the plate so that I could choose the optimum position for the post.

I used a thick piece of hardwood clamped to the table as a drilling guide. I pre-drilled the wood on the pillar drill.

Ready to go. Most bike frames will fit without overhanging the surface at all. The post can be removed in 30 seconds and the wooden top replaced to use as a general work surface.

I’m really looking forward to checking and aligning frames on this table.